CARRY CUBO

I love sitting down and just MAKING something. This drive to create, and my involvement with the EDC (every day carry) community, led me to design a series of soft goods to appeal to gear nerds. I started small and simple, just learning how to sew and making small pouches. As I grew more confident, my goal was to create an experimental brand with a bold design language.

CUBO is the result of this exercise. I took the designs for CUBO from concept to production, and eventually sold my stake in the brand to a friend who was passionate about taking the company to the next level. I remain an advisor to the brand and there are currently 3000 units of product in the United States awaiting the company’s official launch.

Primary Role

Product Designer

Prototyper

Content Creator

Section Guide

1. The Prototypes

2. The Tech Pack and Branding

3. The Factory

4. The Final Products

5. Additional Imagery

The Prototypes

When my partner’s parents gifted me a beginner-level Singer sewing machine, I didn’t expect to get hooked so quickly. Stringing the machine was the most difficult part and my first pouch came together quickly. A backpack is just a LARGER pouch, I suddenly realized, and I got very excited. My first backpack was completed in 2019 and it still sees use today.

After winging a few designs and testing them in the field, my methods became more sophisticated. I started sketching, then transferring my designs to Adobe Illustrator to figure out proper build order and seam allowances. My designs continued to become more complex, and I started experimenting with different fabrics, thread, and hardware.

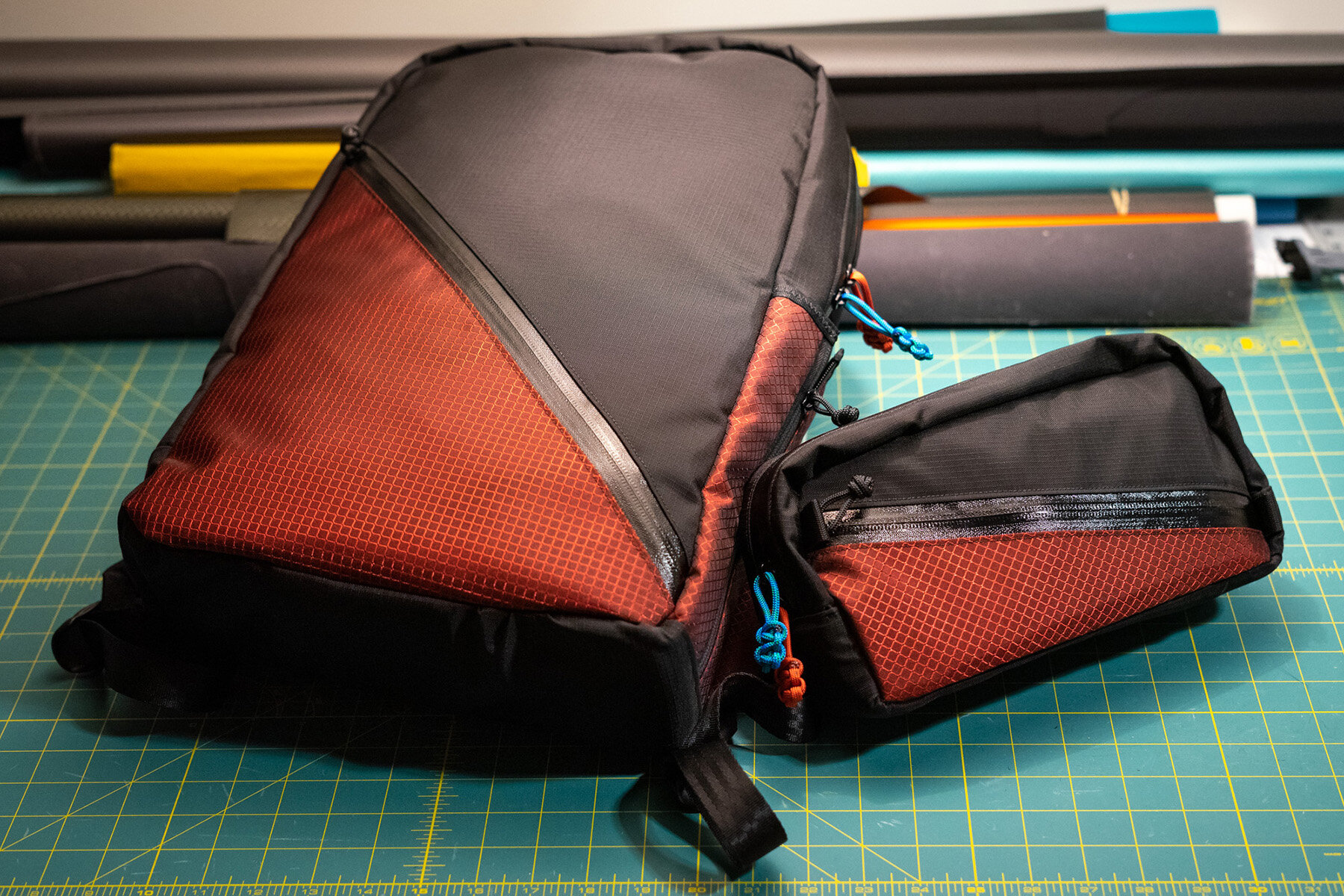

I finally decided to try and make a cohesive set of products with the goal of creating something both functional and lightweight. My living room quickly became a makeshift studio, littered with small component experiments. I tested a variety of designs including different configurations of pockets and different combinations of foam before taking each build out for a test hike and receiving feedback from friends and family to help steer closer to something that would be worth a production run.

One specific piece of feedback I tackled was the back panel being uncomfortable without excessive padding. I was able to combine two different kinds of foam and compress with heat in a wooden mold to create a curved panel with less material.

A friend took an interest in the project as well and assisted with my experiments during this phase.

The Tech Pack.

As I got closer to designs that I was happy with, I needed to figure out how the heck to produce them at scale. The more complex builds could take me a week or more of work in the evenings to cut, stitch and assemble. My living room was also getting pretty tight. I reached out to a few bag makers that I admired on Instagram and got in contact with a designer named Stephen Jones. He was extremely generous with his knowledge and introduced me to a Korean friend of his who had been in the soft goods industry for over 20 years named Richard.

Richard was in the early stages of starting his own manufacturing setup and was eager to help. I had no idea what a “tech pack“ was, so he sent over samples and I got to work translating my messy patterns into legible assembly instructions.

Several rounds were needed on the tech pack before the factory was able to create a workable pattern from our mockups. The design was complex, with over 100 individual pieces and I worked closely with Richard to prototype small components before attempting a full build of the initial bag.

The work began with Richard’s team over Zoom. The calls were long as we navigated language barriers and poor call quality, but everyone remained patient and after 10 rounds of sampling, we had products that were ready for a full production run.

The Factory.

Running production was a multi-phased process where I needed to coordinate component providers, fabric mills, coating facilities, and more to ensure everything arrived on time to Richard and his team. The only way to make sure everything went really smoothly was to travel to Vietnam and spend a few days with their team.

It was a highly productive trip with real-time feedback on a small sample run of 30 bags. We were able to evaluate certain assembly procedures that took up too much time and adjust to help decrease cost and errors. One example is reducing the amount of attachment webbing. Applying so many small barracks was tedious work along the side of the bag. Once we were satisfied with the test production line, Richard moved into the full 3000 unit run.

The Final Products.

It was important to me that the products felt connected visually. Bold color blocking was vital to creating something that was immediately recognizable at a distance without having a huge company name or logo on the product. I’m a big fan of minimal branding and was inspired by product design choices like the iPhone notch. Many hated when Apple added the notch, but it created a strong sense of recognizability around the product. Even with just the silhouette of the phone, you knew what it was, and I sought to achieve the same here.

Additional Imagery.

Additional images of other prototyopes